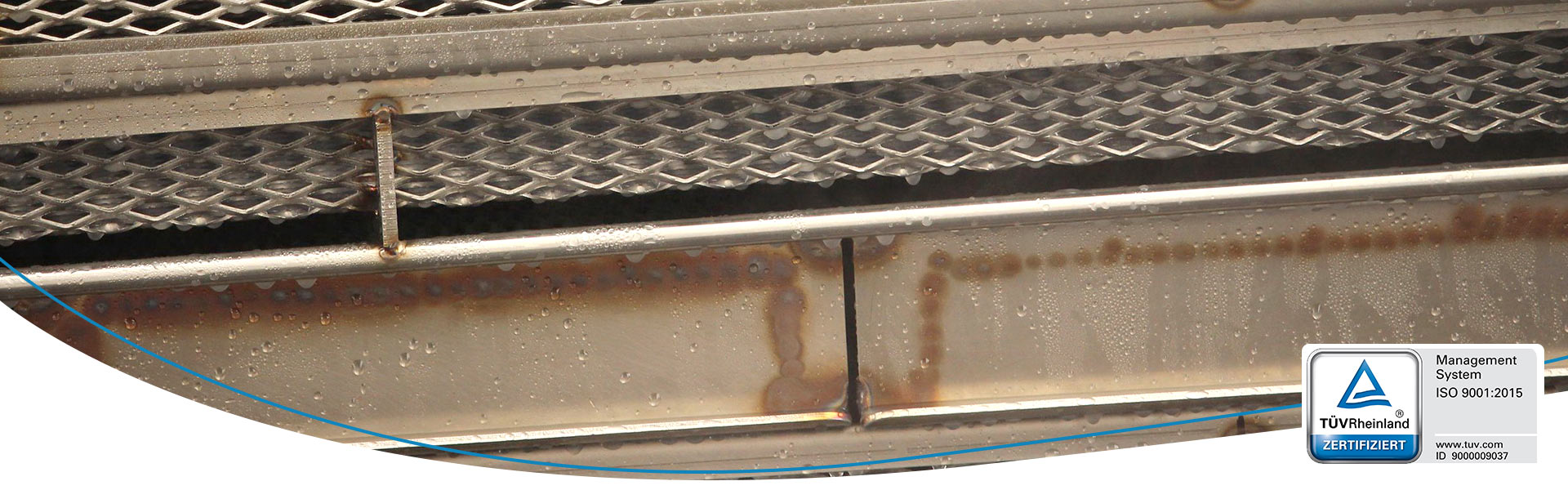

The corrosion resistance of stainless steel is only guaranteed if the surface is free of annealing colors (e.g. after welding processes), residues of drilling emulsions, flash rust or ferritic injections after shaping processes. Acidic and alkaline degreasers/cleaners are recommended for cleaning.

Pickling stainless steels is a chemical process that thoroughly removes impurities and enables a uniform passive layer to be rebuilt.

Depending on the task, construction and surface size, different stain products are used in practice.

Regardless of the process/product used, the stained surface must be thoroughly rinsed, preferably using a high-pressure cleaner. In addition, the application of a passivation solution is recommended for faster formation of a new passive layer.