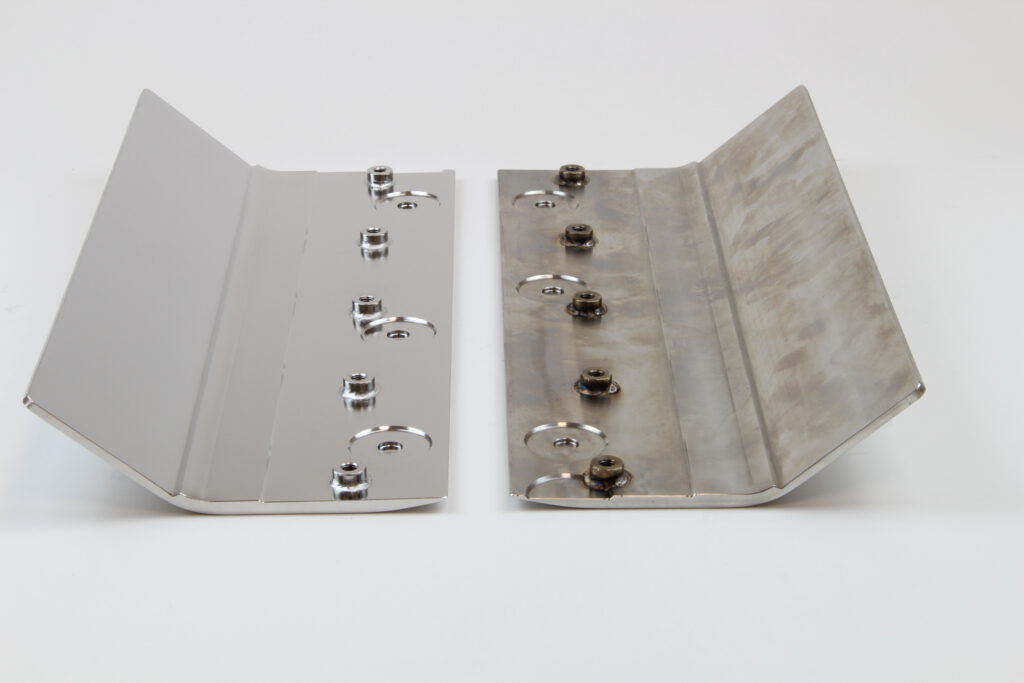

Electropolishing is used for pure metallic surfaces. It reduces the micro-roughness and at the same time has other effects, such as removing all the alloy components of the stainless steel.

Iron, chromium and nickel are subject to this process at the same time. It is based on electrolysis, whereby a current flows through a solution of mostly sulphuric acid and orthophosphoric acid.

The duration of treatment is usually between 2 and 20 minutes.

The process is used for high demands on surface quality such as smoothness, freedom from particles and deposits, corrosion resistance, optical effect (high gloss). Requirements that cannot be achieved by mechanical treatments such as grinding or brushing, but are essential in the manufacture of high-quality consumer goods in apparatus and plant engineering, especially in the food and luxury food industry, pharmaceuticals, medical technology, biotechnology and others.

For removing oils, greases, oxides and other soiling that would hinder even electropolishing.

For smoothing, polishing and deburring the workpiece

To remove electrolyte residues and reaction products, and to dry the metal to prevent stains.